How Acoustic Barriers Work and Why They Are Essential in Modern Industries

Introduction: Why Acoustic Barriers Matter Today

In a world filled with constant noise from traffic, machinery, construction, and household appliances, managing sound has become more important than ever. Acoustic barriers are one of the most effective barrier products designed to control noise pollution, reduce sound transmission, and enhance acoustic comfort in various environments. Whether in automotive design, construction projects, or industrial settings, these solutions play a critical role in improving quality of life, safety, and productivity.

This article explores how acoustic barriers work, where they are applied, and why they remain the top choice for industries seeking both sound insulation and vibration control.

What Are Acoustic Barriers and How Do They Work?

Acoustic barriers are flexible, sound-insulating barrier products specifically designed to minimize airborne noise and impact sounds. Their primary function is to prevent transmission loss—meaning they stop sound from passing through surfaces like walls, panels, or enclosures.

Unlike regular insulation materials, acoustic barriers not only absorb sound but also act as anti-vibration pads, reducing the rattling and impact noise that often accompanies heavy machinery or moving vehicles. Many advanced barrier products can also reflect thermal radiation, making them effective in environments where heat and noise are both challenges.

Some standout features of acoustic barriers include:

- Excellent sound insulation across different frequencies

- Strong vibration-dampening performance

- Ability to be applied to flat, curved, or uneven surfaces

- Compatibility with acoustic foams to create custom noise-reducing laminates

Where Can Acoustic Barriers Be Used?

The versatility of barrier products makes them suitable for a wide range of industries and applications. Here are some common uses:

- Automotive Sector – Acoustic barriers are used in cars, trucks, and buses to reduce engine noise, road vibration, and rattling panels.

- White Goods & Appliances – In products like washing machines, dishwashers, and refrigerators, barriers reduce operating noise.

- Lift Cabins & Metal Furniture – They provide quiet operation and improved user experience.

- Construction Machinery – Essential in tractors, excavators, and earth-moving vehicles to protect operators from excessive noise.

- Steel Sinks and Tubs – Reduce the loud echoing sound of water impact.

- Pipe Insulation – Prevents vibration and noise from fluid or gas movement.

- Marine and Aerospace – Barrier products are applied in ships, yachts, and aircraft for both noise and thermal protection.

In every case, acoustic barriers not only reduce noise but also extend the durability and comfort of the products or spaces they are applied to.

See also: Catering Equipment Suppliers Shrewsbury: Support for Every Kitchen

Types of Acoustic Barrier Products: Choosing the Right Solution

1. Polymeric Acoustic Barriers

These are low-density vinyl membranes (like C03 and C09) designed to improve insulation in panels made of wood, metal, or plastic. Their main advantage lies in overcoming resonance in lightweight composites such as plywood or hollow-core panels.

Best suited for:

- Automotive interiors

- Lightweight furniture

- Soundproofing panels

2. Bitumen PE Foil Covered Barriers

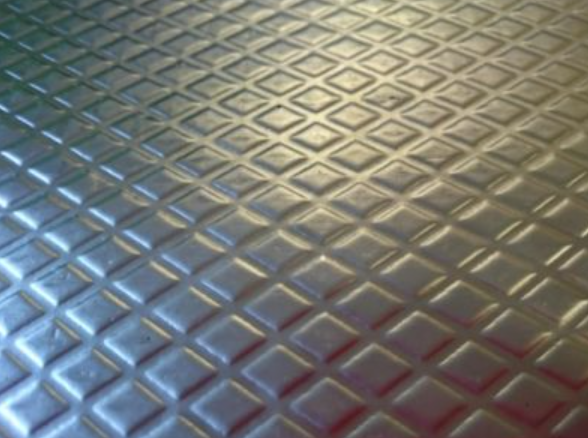

Models like C022 and C023 feature a diamond-embossed PE face with self-adhesive backing. They excel in flat applications, preventing transmission loss and adding anti-vibration performance. The PE foil keeps the installation clean by stopping seepage from the bitumen layer.

Best suited for:

- Flat wall or panel insulation

- Household appliances

- Industrial enclosures

3. Bitumen Aluminium Acoustic Barriers

The C024 model is a laminated mix of bitumen, polymers, and mineral fillers protected by aluminium foil. The aluminium face makes it perfect for high-heat environments like engine blocks and construction vehicles.

Best suited for:

- Engines in cars, construction machinery, and agricultural vehicles

- Marine applications

- High-temperature industrial environments

Foam Conversion: Enhancing Acoustic Performance

To maximize performance, many companies combine acoustic barriers with foam products through a process called foam conversion. This involves cutting, laminating, or molding foam into specific shapes to complement the barrier’s properties.

Foam types commonly used include:

- Polyurethane foam – For cushions, insulation, and packaging

- Polystyrene foam – Lightweight, ideal for insulation and packaging

- Polyethylene foam – Durable and moisture-resistant, perfect for industrial padding

When laminated with acoustic barriers, these foams create bespoke solutions tailored to unique soundproofing challenges—such as controlling radiator noise in vehicles or insulating yacht engine rooms.

Benefits of Acoustic Barriers: Why Industries Choose Them

1. Improved Productivity

By lowering noise in industrial settings, acoustic barriers reduce worker fatigue and improve concentration.

2. Enhanced Comfort

In cars, appliances, and furniture, barriers make daily life quieter and more enjoyable.

3. Versatility

Barrier products can be applied across industries—from construction to marine to healthcare.

4. Safety & Compliance

Excessive noise can cause hearing damage. Barriers help companies comply with health and safety regulations.

5. Durability

High-quality barriers withstand heat, vibration, and environmental conditions without losing performance.

When Should You Use Acoustic Barriers?

You should consider installing acoustic barriers when:

- Noise exceeds safety limits in workplaces or public spaces

- Machines cause excessive vibration that impacts performance

- Products need thermal and sound insulation (e.g., sinks, appliances, vehicles)

- You want to improve comfort in residential or commercial spaces

Top Industries Driving the Demand for Acoustic Barriers

- Construction & Infrastructure – Noise-reducing panels for buildings and highways

- Automotive & Aerospace – Soundproof cabins and heat-resistant barriers

- Marine Sector – Engine room sound insulation in yachts and ships

- Manufacturing & Appliances – Quieter machinery and home appliances

- Healthcare – Noise reduction in hospitals and medical equipment

Conclusion: The Future of Acoustic Barriers

As urbanization, industrial growth, and environmental awareness continue to rise, the demand for acoustic barriers will only increase. These barrier products are no longer just add-ons but have become essential components in design and engineering, ensuring compliance, comfort, and sustainability.

By integrating innovative materials such as polymeric membranes, bitumen foils, and foam composites, modern acoustic barriers are capable of solving complex sound problems across industries. Whether you’re building vehicles, manufacturing home appliances, or constructing commercial spaces, investing in the right barrier products ensures a quieter, safer, and more efficient future.